EO Sterilization: Why It’s Still the Gold Standard for Medical Device Manufacturers in India and Best Choice for IV Cannulas

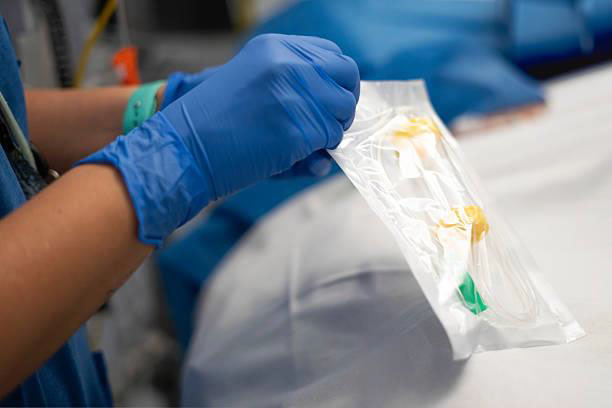

When it comes to patient safety, sterilization isn’t just a process; it’s a promise. And in the world of disposable medical device manufacturers in India like IV cannulas, catheters, and infusion sets; Ethylene Oxide (EO) sterilization remains the most trusted and effective method, even in 2025.

But why is EO still the industry standard? And why do global manufacturers continue to rely on it despite the availability of other methods like gamma radiation or steam?

Let’s break it down.

What Is EO Sterilization?

Ethylene Oxide (EO) is a colourless, odourless gas that sterilizes by alkylating the DNA and proteins of microorganisms, including bacteria, viruses, and spores. It doesn’t rely on heat or moisture, which makes it ideal for heat-sensitive and moisture-sensitive devices.

EO is particularly effective for devices with complex geometries, porous packaging, or plastic components, a category that includes most single-use medical devices.

Why EO Is Still the Gold Standard?

Deep Penetration into Complex Devices

EO gas diffuses through plastic layers, lumens, and even sealed packaging. This makes it far more reliable for devices with:

- Multiple components (e.g., cannula + wings + catheter + cap)

- Protective blister or Tyvek® packaging

- Narrow or closed channels

Gamma or steam sterilization often struggles to reach inner surfaces, especially in sealed or multilayered setups.

Compatible With Sensitive Materials

EO works at low temperatures (typically between 37°C – 63°C), which makes it perfect for:

- Thermoplastics like FEP or PU

- Medical-grade adhesives

- Printed or color-coded components

Other methods, especially autoclaving or high-energy radiation, can degrade plastic parts causing discoloration, brittleness, or warping.

Preserves Product Integrity and Shelf Life

EO sterilization, when done correctly, doesn’t compromise:

- Catheter flexibility

- Needle sharpness

- Seal strength of packaging

- Colour markings or measurement indicators

This ensures that devices stay shelf-stable for 3 to 5 years or more, a major advantage for bulk hospital stocking and exports.

Highly Validated & Regulated

EO sterilization is supported by robust international standards like:

- ISO 11135:2014 – Validation and routine control

- EN 550 – Packaging validation

- ISO 13485 – Overall quality system alignment

This level of standardization ensures consistency, traceability, and confidence especially during audits by hospital procurement teams, regulatory bodies, and export agencies.

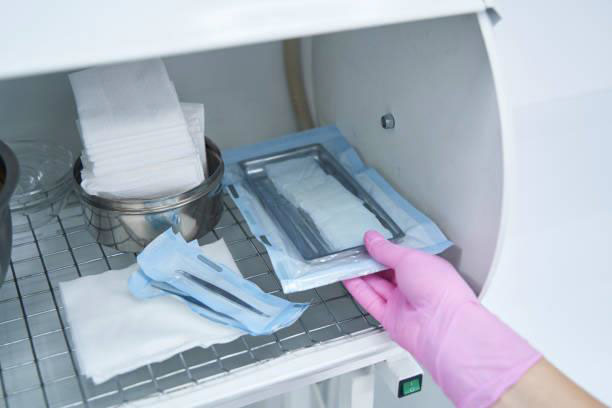

Sterile, Tamper-Proof Packaging

- Scalable for Mass Production

For manufacturers like Cubit MediSurge, EO offers the ability to sterilize thousands of units in a single validated cycle, with:

- Customizable cycle parameters (gas concentration, temperature, humidity, etc.)

- In-house or outsourced batch testing (biological indicators, residual analysis)

- Batch traceability with full documentation

It’s safe, repeatable, and economical at scale.

Common Myths About EO — Debunked

- Myth 1: EO is harmful to patients.

Truth: Devices are thoroughly aerated post-sterilization. EO residue levels are tested and controlled under ISO and FDA limits, ensuring safety. - Myth 2: Gamma sterilization is “newer” and better.

Truth: Gamma can degrade certain materials. It’s great for some devices but not for soft plastic-based consumables. - Myth 3: EO is outdated.

Truth: EO is still used by global Medtech leaders. It’s continuously evolving with better containment, emissions control, and safety validation.

How Cubit MediSurge Ensures EO Sterility, Every Time?

1. ISO 11135-compliant protocol design

2. Biological Indicator testing for every cycle

3. Regular residue testing to ensure residual EO, ECH, and EG are within safe limits

4. GMP-trained quality assurance team for full compliance

5. Detailed batch-wise documentation for export and traceability Our EO processes are continuously audited and supported by strong quality systems to ensure that every IV cannula that reaches your hands is safe, sterile, and stable.